Affordable Sycamore Fence Installation

Have a professionally installed fence in Sycamore built right the first time. Our licensed professionals take care of permitting, homeowner association clearance, utility location services (811), and property boundary verification. We plan layout, set posts to frost depth, align rails, and hang gates to spec. Select from various materials including wood, vinyl, composite, decorative metal, or chain link-complemented by corrosion-resistant hardware and warranted finishes. Get accurate measurements, drainage considerations, complete inspections, and documented timelines and warranties. Discover which materials, designs, and schedules work best for your property.

Critical Findings

- Local, licensed fence specialists in Sycamore managing required documentation and inspections with verified property line and utility clearances.

- No-cost on-site evaluations, precise layout, and scaled site plans for setbacks, drainage, gates, and slopes.

- Expert installation: posts secured to frost depth, including accurate alignment, anti-corrosion hardware, and foundation footings crowned for water runoff.

- We offer diverse material selections featuring vinyl, composite, cedar/PT wood, ornamental metal, and chain link featuring code-compliant heights, pool-safe spacing, and finish warranties.

- Clear timelines and warranties; service packages feature once-a-year fastener checks, surface refinishing, and drainage improvements.

Why Choose Professional Fence Installation in Sycamore

Launch with professional knowledge that avoids costly mistakes: professional fence installers in Sycamore know ground composition, property lines, and municipal codes, making certain your fence meets setback, height, and visibility requirements the first time. You'll prevent property line issues, encroachments, and correction orders because professional teams check boundaries, arrange for utility locates, and record approvals. Their technical know-how establishes post depth, footing size, drainage allowances and gate clearances that maintain lasting compliance.

You'll also get liability protection. Reliable contractors maintain general liability and workers' compensation, safeguarding you from property damage and injury claims. They implement code-approved fasteners, weather-resistant materials, and secure installation methods, and deliver warranty protection and installation records. With accurate layout, plumb lines, and tensioning, your fence performs optimally and passes inspection without delays.

Residential and Commercial Fencing Materials and Designs

Once you have the permitting and layout properly arranged, you can direct your attention to picking fence materials and styles that comply with Sycamore's performance, maintenance, and code requirements. For reduced upkeep, choose recycled composite panels; they withstand rot, insects, and warping while conforming to height and setback standards. Wood delivers warmth but demands sealing; cedar or treated pine performs best with code-appropriate post depth and fasteners. Chain link offers economical security; incorporate privacy screens where authorized to enhance opacity without exceeding height limits. Ornamental metal (steel or aluminum) delivers durable, pool-compliant options with code-specified picket spacing. Vinyl is stable, cleanable, and suitable for residential boundaries. Bamboo fencing can serve as a decorative screen; check local allowances for wind load and decay resistance. Be sure to verify gate hardware, visibility, and clearance requirements.

Customized Solutions: Aligning with Your Property's Style and Requirements

Remember to align the fencing style with your property's architectural style to create a harmonious appearance and adhere to local design requirements. Pick materials and finishes that coordinate with existing features, satisfy durability requirements, and comply with HOA and building codes. Layout access points, sightlines, and setbacks to maximize access and safety while complying with height restrictions, easements, and spacing requirements.

Architectural Style Alignment

While fence height, setbacks, and materials must comply with local code, achieving the best results comes from matching the design to your property's architecture and functional needs. Start by identifying your home's primary design theme-Colonial, Craftsman, Contemporary, or Mid‑Century-and mirror its patterns, proportions, and elements in the fencing design and post placement. For heritage conservation areas, follow approved guidelines, protect significant sightlines, and detail any suggested aesthetic differences to demonstrate harmonious integration.

Align highest points to porch railings and roof angles, keep gate spacing fits path layout, and scale posts to building mass. Preserve transparency near primary elevations to protect streetscape character and sight triangles. Integrate corner returns, datum lines, and trim profiles for consistency. Verify setbacks, sight-distance requirements, and easements before layout to establish appropriate, harmonious alignment.

Materials and Finishes Available

Few decisions influence strength and integration more substantially. Choose substrates that satisfy regulatory standards, weather requirements, and maintenance goals. Budget-friendly pressure-treated pine works well and readily accepts stains; cedar and redwood feature built-in oils and excellent climate protection. For maximum durability, choose powder-finished steel or aluminum with AAMA-compliant finishes; in maritime environments, specify marine-grade alloys. Vinyl delivers consistent color and minimal maintenance but demands ultraviolet-resistant compositions.

Align surface treatments with surrounding elements and modern |Fence Sales Of Sycamore color patterns without sacrificing longevity. Implement deep-penetrating finishes on wood to reduce peeling; choose eco-conscious solutions where required. For metals, specify galvanized or zinc-aluminum substrates under powder coating. Verify hardware: stainless fasteners, appropriate mounting hardware, and isolation barriers to prevent galvanic corrosion. Secure maintenance schedules and warranty terms with written verification.

Efficient Space Planning

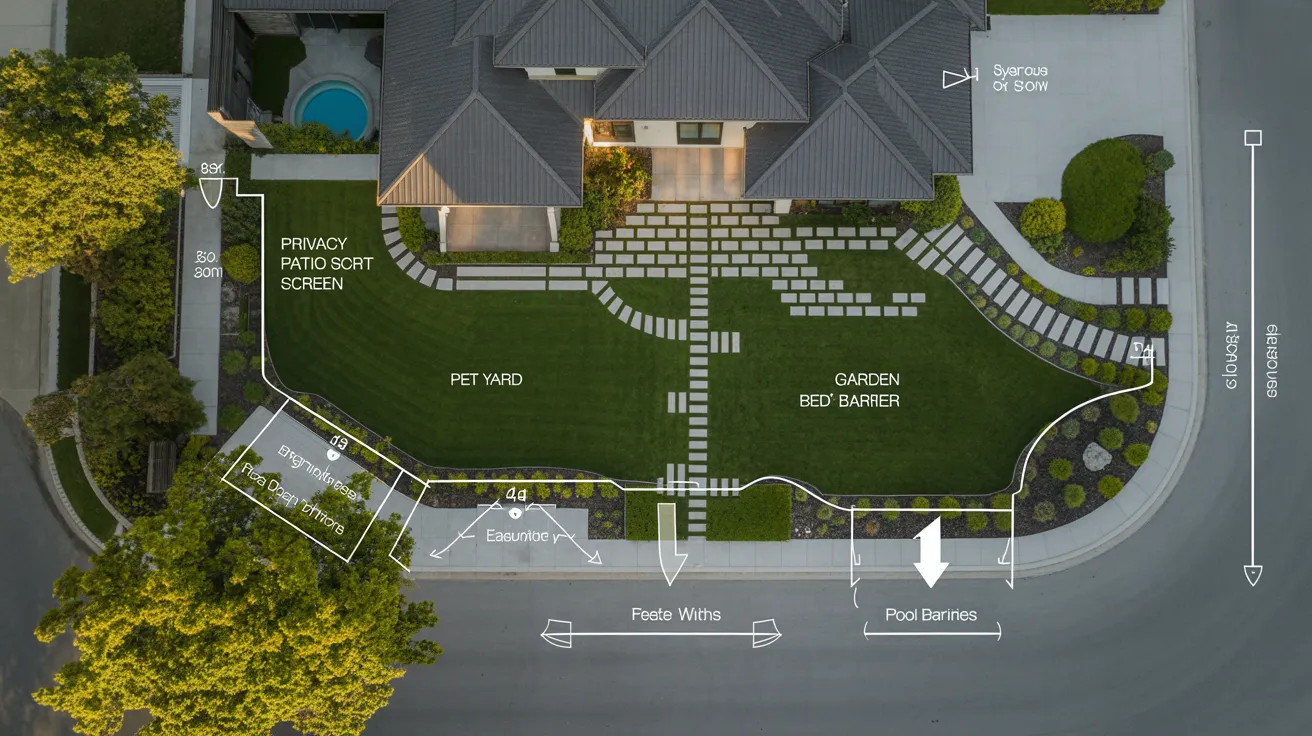

Before planning fence boundaries, start by establishing functional zones and verify compliance with local regulations and site limitations. Map out key access points, vehicle paths, and service zones to maintain efficient flow. Define spaces for privacy, pets, swimming pools, and gardens, then size all gates to accommodate maintenance equipment and emergency access. Locate gates carefully to ensure easy reach to service meters, utility controls, and access rights; don't obstruct established rights-of-way.

Ensure fence specifications align with city ordinances and community rules for height, opacity, and setbacks. Keep appropriate sight lines at corners and ensure proper drainage pathways to prevent water accumulation near structures. Arrange posts in relation to ground conditions and mounting positions to ensure structural integrity. Use heavy-duty components on high-traffic access points. Configure lights and gate hardware to meet safety codes, especially around pool areas. Record all measurements in a scaled drawing.

Permits, Building Codes, and Property Boundaries

Before proceeding with your fence construction, you need to confirm local permitting, zoning, and code requirements before any post placement. Obtain written approval for placement, materials, and height, and confirm zoning setbacks for streets, alleys, and easements. Check HOA covenants when applicable. Contact 811 and document utility clearances before excavation; most localities need documentation. Complete boundary verification to verify the legal property limits; avoid depending on previous fence lines or suppositions. If markers are missing, hire a professional surveyor.

Comply with sight-triangle requirements at corners and meet pool safety standards and wildlife protection rules when applicable. Secure neighboring property consent when constructing near shared property lines; formal approval reduces future disputes. Store permits on-site and arrange required inspections when required. Preserve records-such as approvals, surveys, and notifications-for final approval.

Project Planning, Site Assessment, and Measurements

Commence by analyzing the property layout, noting grade changes, utilities, easements, and required setbacks to verify compliant fence placement. Set up accurate measurement protocols: create control lines, fix benchmarks, calculate center-to-center post spacing, and record offsets for gates and corners. Record all dimensions and constraints in a site plan to guide material takeoffs, cut lists, and a code-compliant installation procedure.

Layout Configuration Analysis

Although the fence style and materials matter, your project succeeds or fails with a thorough site assessment. Initially confirming property boundaries against recent survey documents and recorded easements; indicate setbacks as per local code. Identify utilities via 811 and record overhead clearances. Complete a vegetation survey to locate trees, roots, and invasive species that may conflict with post locations or long-term stability. Execute drainage analysis to track slope, low points, and discharge paths so fence lines won't create water buildup or compromise footings. Note driveway aprons, ADA routes, gates' swing arcs, and required sight triangles at streets. Review soil classifications and frost depth to guide footing design. List surface improvements-retaining walls, patios, irrigation-so alignment stays code-compliant and constructible.

Accurate Measurement Protocols

After verifying the site constraints, establish a fixed baseline and datum, then measure from control points to eliminate cumulative error. Use benchmark markers positioned outside excavation limits. Confirm property corners with survey equipment and resolve any deed, plat, or GIS discrepancies. Complete laser calibration before layout; confirm instrument level and compensate for slope. Extend measuring lines or use a total station to set fence lines, offsets, and gate clearances. Log horizontal and vertical data, including post height measurements, drainage fall, and utility separations per code. Indicate post centers at specified spacing, modifying for corner, end, and gate posts. Validate diagonals to verify squareness. Record tolerances, required clearances, and obstructions. Maintain all control points until concrete cures and final inspection.

Installation Process: From Post Setting to Final Finish

Begin with precise layout and code verification, then you'll establish corners, extend your lines, and indicate post centers at compliant spacing. Create holes to frost depth, shape hole bases as needed, and secure posts in 5:1 gravel-concrete mix, crowned for drainage. Check plumb and post alignment with a level and stretched line; support until cure. Attach rails per manufacturer span specifications, prepare fasteners, and keep consistent reveal at gates and terminations. Place panels or boards with consistent gaps and corrosion-resistant hardware. Adjust top line for grade, then trim posts to specified height. Cap or flash posts where required. Finish exposed cuts, treat end grain, and apply finish selection to match local guidelines. Conduct a final walk-through, verifying clearances, fastener torque, and code compliance.

Durability, Maintenance, and Warranty Details

While visual appeal is important, lasting performance depends on material choices, protective coatings, and maintenance intervals. Choose materials designed to withstand weather conditions, then combine them with weather-resistant hardware to avoid metal deterioration. Specify concrete footings below frost depth and implement ultraviolet-protective sealants following manufacturer recommendations. For environmentally conscious options, choose sustainably sourced lumber or eco-friendly composites that meet local regulations and fire ratings.

Perform annual inspections to secure all fasteners, prevent ground contact, and refresh coatings as required. Ensure proper drainage to stop water wicking. Immediately swap out compromised fencing pieces and deteriorated caps to prevent further issues.

Review warranty terms in writing. Request extended protection for materials and installation quality, with specified restrictions, ability to transfer, and upkeep specifications to keep protection valid.

Request a Local Estimate and Schedule for Your Fencing Project

Secure an accurate estimate by getting comprehensive estimates from insured, licensed fence installers in your zip code, specifying fence type, height, linear footage, gate requirements, and site conditions. Request each contractor to validate utility locates, property line assessment, and code compliance. Ask for a written timeline projection detailing setup, post setting, concrete curing, panel mounting, and inspection dates.

Confirm who manages permits, homeowner association clearances, and inspection coordination. Supply specifics on ground conditions, tree root locations, terrain gradients, and access constraints so crews can properly quote equipment and labor costs. Ask for itemized pricing for debris removal, rock drilling, high-grade concrete, and gate accessories. Evaluate and assess craftsmanship warranties and material details by product code. Define progress benchmarks with payment triggers linked to inspections. Secure project dates in writing, with weather allowances and change-order provisions explicitly defined.

Questions & Answers

How Do Weather Seasons in Sycamore Influence Installation Times

Seasonal weather patterns in Sycamore plays a crucial role in installation scheduling. Installation teams skip winter construction periods to prevent frost damage affecting post stability and cement setting. Best scheduling windows are late spring or early fall for consistent soil composition and reliable weather. Projects plan around wet weather patterns to preserve excavation integrity and proper bearing capacity. In peak allergen periods, special care protects coating applications, while adhering to building codes for depth regulations, drainage guidelines, and placement verification to ensure lasting results.

Can Gates Be Connected to Smart Locks and Access Control Systems?

Indeed. It's possible to combine gates with access control systems and smart locks. We provide smart entry with RFID, keypad integration, Wi‑Fi controllers, and Bluetooth. We'll recommend secure enclosures, weather‑rated hardware, and UL‑listed power supplies. We coordinate grounding, low‑voltage wiring, conduit, and surge protection to satisfy NEC and local requirements. You'll get app control, schedules, audit logs, and remote overrides. We also set up fail‑secure/fail‑safe according to fire and egress code.

How Can You Finance Your Fence Project?

Choose between flexible payment terms, promotional zero-interest periods, and delayed payment options pending qualification. We offer phase-based payment schedules that coordinate with construction phases. You'll receive straightforward terms with all costs clearly stated and fully compliant documentation. We support you in financial planning, incorporating material alternatives and scope modifications to achieve your financial goals. Process transactions through electronic transfer, card payment, or check. Contact us regarding prepayment benefits and flexible financing options for larger projects.

Do You Handle Old Fence Removal and Recycling?

We manage environmentally responsible removal of old fencing. Many clients call the day their new fence arrives, worried about material disposal. Don't worry. We safely dismantle posts, rails, and footings, separate metals, wood, and composites, and send them to certified recyclers or compliant landfills. We cap concrete, comply with local standards, supply disposal documentation, and ensure a tidy workspace. You review and confirm; we document and haul.

What About HOA Approval Support Services - Do You Provide Drawings and Documentation?

Absolutely, you receive complete HOA approval support. We deliver HOA advisory services, develop scaled drawings, specifications, and material data, and compile essential forms. We coordinate permit applications simultaneously, verifying setbacks, height limits, and visibility standards meet code and HOA covenants. You get certified drawings when needed, photo simulations, and timely revisions. We handle packets, follow reviews, respond to comments, and obtain final approvals so you can schedule installation efficiently.

Concluding Remarks

Perhaps you're thinking of eyeball the property line, bypass official permissions, and be left with a fence that tilts like modern art. Rather, allow specialists to manage proper measurements, spacing, and certified products, making sure your installation is precise and keeps the peace next door. We promise seamless integration with your property, thorough documentation, and expert installation accounting for ground conditions to weatherproofing. You'll receive a thorough final review, firm project timeline, and a flawless barrier that's properly aligned, permitted, and perfect.